Açıklama

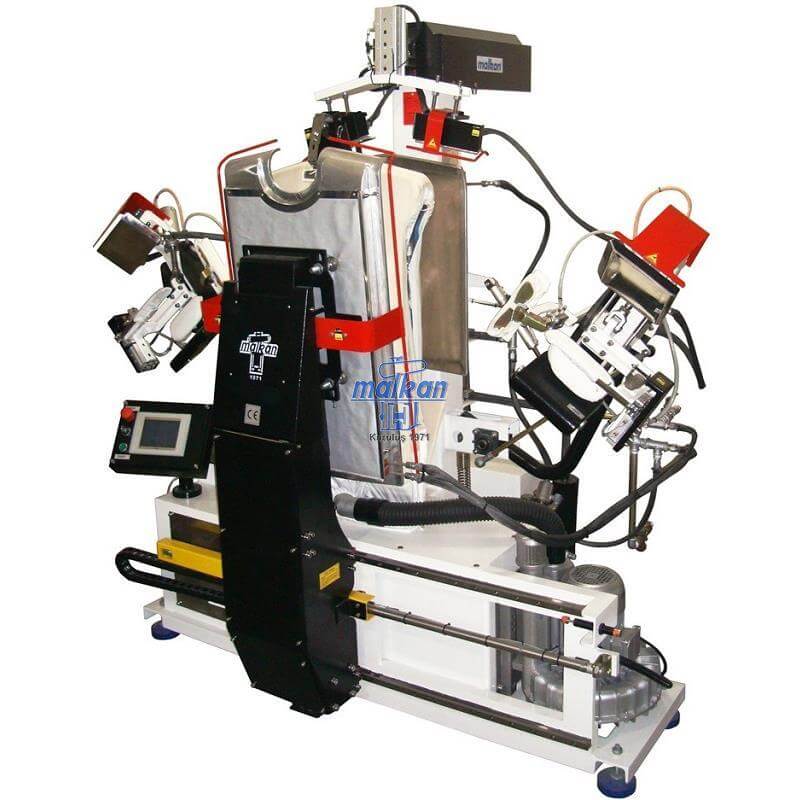

GUR01 PNEUMATIC SHIRT IRONING ROBOT

- The moist shirt is ironed and dried with pressure and hot air

- Vertical mobility in the upper mold

- PLC controlled, 7” color LCD touch screen

- 800 x 480 Pixel resolution, 16.7M colors

- Ethernet, RS232C, RS422/485 communication ports

- 1 Usb 2.0 input (program receiving feature on the desktop)

- 100+ different ironing programs and program copy feature

- Turkish and English standard programming languages (12 different language options)

- Fast breakdown finding with fault warning diagnostics and saving feature

- Manual function control via touch screen

- Digital press pressure setting; 0.1 bar sensitivity via screen

- Counting the number of ironed jobs and coating time warning

- Program lock key (to prevent unauthorized use)

- Safe operation and long coating life with upper molds with mechanical locking system

- Vacuum and steam in the lower mold (mannequin)

- With the mannequin vacuum system, the hems of the shirt are placed properly

- Powerful hot air blowing system with speed control / flow rate adjustment

- Proper placement with collar gripping apparatus

- Arm cuff fastening-stretching and heated cuff ironing apparatus

- Automatic arm stretching according to shirt sleeve length

- Error-free ironing with adjustable shirt sleeve angle

- Ironing with separate pressing on the shoulders and puffing on the sleeves

- Ironing different sizes with side stretching and puffing function

- Safety ring for operator safety

- First class coating materials

- Fast heating and energy saving with steam serpentine system and isolated molds

- Accurate mold design with advanced technology CNC surface machining

- Works with central steam, vacuum, air and 380 V electricity

- MALKAN ONLINE remote access and monitoring system (optional)

- Program list recall with barcode or QR code (optional)